Oracal Vinyl Color Chart Series Is The

Available in 60 gloss colors plus transparent, matte white and matte black. This color guide is made from actual material and you will have a good reference for what color youre going to get for your next project.5+ Year Outdoor Durability / Metallics 4-yearOracal 651 Permanent Vinyl Color Chart 64 COLORS Semi-Editable PSD Oracal Vinyl Color Chart Oracal 651 Color Chart 651 Color Chart GFXGrove 5 out of 5 stars (484)Oracal 651 is a permanent adhesive backed vinyl. Oracal 6510 - This series is the fluorescent (neon) colors of Oracal 651.

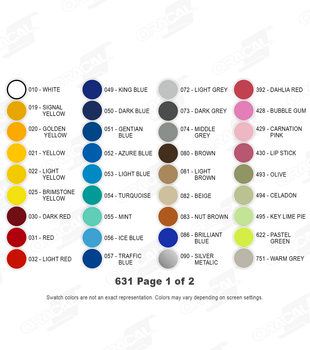

Works well with non porous surfaces such as glass and stainless. Our wide selection is elegible for free.Oracal Adhesive vinyl is the best to use for hard surfaces!ORACAL 8800 Translucent Cast Film - Black. When you want a Black Translucent film with 10 year durability and the performance of a cast vinyl, you want this ORACAL® 8800 Black Premium Cast film. 2 mil thick, this vinyl is perfect for backlit signs, window and architectural glass applications due to its satin finish and light transmission characteristics.Here is a break down of the types of Oracal vinyl sold at Swing Design:ORACAL 631 Intermediate Calendered Film Color Chart Oracal 631 vinyl is an ideal choice for indoor wall signage and indoor decoration due to its no-glare matte finish and removable adhesive.

NEW ORAJET 3169RA - Window, Wall & Floor Application Video NEW ORACAL 8300 & 8510 Architectural Window Graphic Application NEW ProSlide™ Advanced Repositionable Adhesive Technology After application let sit at least 24 hours, we recommend 72 hours.

NEW ORACAL 970RA Vehicle Wrap Application Video ORACAL® 851 Screen Printing Glitter Stickers ORALITE® V98 Reflective Chevron Striping Application Video

ORACAL® 970RA Premium Shift Effect Cast NEW ORACAL® 970RA UNIQUE Colors by Will Castro Designs NEW ORAGUARD 289F Over-Laminate / PPF Self-Healing & Puncture Demonstration NEW ORALITE 5600RA Fleet Engineer Grade Reflective Wrap Film Application Video NEW ORAJET 3954 Brick & Stone Textured Wrap Film Application Video

Graphic Innovations ORALITE® 5600RA New Product Flyer Plotter Films Product Selection Tool - Good, Better, Best Guide Reflective Solutions ORALITE® Brilliance® Series Sealed Prismatic Trims

Adhesive Tape Systems for Sign & Display Markets Reflective Solutions for Emergency Response Brochure Reflective Solutions for Vehicle Conspicuity Brochure Reflective Solutions ORALITE® GP330 Product Flyer

Matte/Satin: This formula has been developed specifically for matte car wrapping films and is water-free with a very high carnauba wax content.Achieve the highest possible degree of protection with ORACAL ® cleaning and care agents. Gloss: This formula has been developed specifically for glossy car wrapping films and will provide an extremely smooth surface with a unique deep gloss. ORACAL ® Long-Lasting Seal provides long-term protection for your car wrapping film, and should be applied once every 3-6 months for the life of the wrap.

Oracal Vinyl Color Chart Trial Pollutants That

Also, our cast films tend to be more conformable and durable for demanding longer-term applications.I have applied a decal using ORAJET ® vinyl to my car window. The solvent adhesive will last much longer when exposed to changing surface temperatures, chemicals and mild solvents. While you can obtain more specific application recommendations in the product section of our website, as a general rule we recommend the use of films with a solvent-based adhesive for automotive use. Caution: Many cleaning agents can leave a residue that either prevent vinyl adhesion or attacks the vinyl adhesive, such as Windex ® (and other glass or surface cleaners), Rapid Prep ®, and degreasers.What should I use if IPA (isopropyl alcohol) has been used to clean glass and there still seems to be a surface residue preventing vinyl adhesion?We have found that Bon Ami ® glass cleaner should remove any chemical residues left behind by other glass cleaners.Does ORAFOL recommend any of its products for stainless steel tank applications?Due to the wide variety of stainless steel types, gauges, applications, and aggressive cleaning regiments, ORAFOL Americas does not warranty its products when applied to stainless steel tanker trailers.Which kind of ORAFOL films are suitable for making decals for automobiles?ORAFOL offers a wide range of graphic marking films and digital media that are suitable for automotive decals. Please see the Dealing with Fallout practical information flyer for more information.What is the best cleaning solution to use for prepping substrates prior to application with ORAFOL films?IPA (isopropyl alcohol) is generally recommended unless the substrate manufacturer states that there is an incompatability. What causes this condition?While we can’t say for sure without proper samples and photographs of the actual vehicle, you’re probably seeing the result of “acid rain” or “fallout”, which we believe is caused by industrial pollutants that condense on the films surface in the form of dew when vehicles are left in the elements.

ORACAL ® 8300 is thermal print compatible and suitable for both wet and dry application. ORACAL ® Series 8300 is designed for permanent, durable, internally illuminated signs and window graphics. Wipe away any residue left behind with Isopropyl Alcohol and a clean rag.Is ORACAL ® Series 8300 suitable for use on vehicle headlights and taillights?No, ORAFOL assumes no liability for the possible damage that may be caused upon removal of its Series 8300 material from vehicle headlights and taillights. Peel up an edge of the decal and slowly pull back until the graphic is removed. Hold the heat gun 6-9″ away from the decal dispersing the heat evenly over the surface of the decal for about 10-15 seconds.

Wipe the vehicle with ORACAL ® Pre-Wrap Surface Cleaner or isopropyl alcohol just before the installation to remove any soap residue or dust. Nooks and crevices are likely to trap moisture, and will result in poor adhesion. The vehicle should be washed and allowed to dry for 24 hours before wrap installation. ORACAL ® 351 and 352 are not designed for vehicle wrapping.How do I prepare the vehicle surface prior to applying a vehicle graphic?Click here for complete Pre-Application & Application GuidelinesThe surface of the vehicle must be free of dust, grease, or any other contamination that could keep the film from adhering properly. Since these are metallized films, these films are very rigid and offer no conformability to curved surfaces.

The graphics must be stored in a controlled environment between 65☏ and 75☏ for a minimum of 24 hours prior to installation to promote an ideal application experience and performance.Yes. It is also possible to go over these areas with a heat gun to help drying.Keep the vehicle in a controlled environment at the minimum temperate of 59☏ during the drying time. Nooks, crevices, and under rubber seals should also be cleaned with one of these agents to promote proper adhesion into these areas.

We do not recommend applying this product to porous concrete, asphalt or masonry surfaces.What floor graphic material does ORAFOL recommend for Social Distancing and other promotional floor graphic applications? Series 1663 can adhere to most smooth, sealed surfaces. For durability and anti-skid properties we recommend combining this product with ORAGUARD® Series 250AS Laminating Film or ORAGUARD® Series 255AS(High Traffic Load)Laminating Film.

We applications should only be done in ambient temperature environments of at least 60☏. Commercial Grade Carpet, consider ORAJET ® 3165, 3651, or 3105HT digital print media and over-laminate with ORAGUARD ® 250AS or 255AS Anti-Skid textured floor laminate.Click here for complete Processing and Handling Floor Graphic InstructionsWhat does ORAFOL recommend when performing a wet application with its products?Wet applications are typically recommended for large surface applications of solvent-based adhesive products being applied to architectural glass and windows. Exterior surfaces such as asphalt or concrete, consider ORAJET ® 3105HT, 3951HT, or 3954 digital print media and over-laminate with ORAGUARD ® 250AS or 255AS Anti-Skid textured floor laminate.

0 kommentar(er)

0 kommentar(er)